We provide the backbone for competitive manufacturing

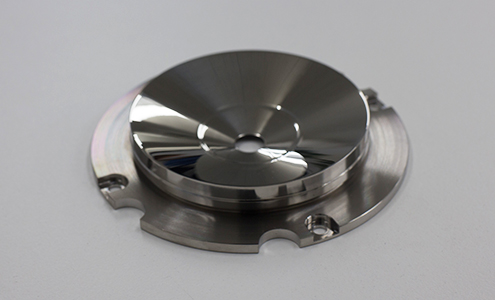

Since it is possible to perform one-stop processing from lathe processing, machining processing, grinding processing, and assembly, including compound lathe processing, which is the specialty of Nadaka Corporation. It is possible to propose the best construction method for the entire product, not for individual parts. In addition, with more than 100 Sei-san facilities with various characteristics We have a wide range of measuring equipment, which can handle a wide variety of materials such as heat-resistant steel and other difficult-to-cut materials, iron, stainless steel, aluminum, copper, etc. The material can be processed. We have acquired ISO9001: 2015 certification in Japan and IATF1649: 2016 certification in Thailand, and we manufacture products under quality control that gives our customers peace of mind. We will provide products that are trusted by our customers with the "Challenging Manufacturing DNA" that we have built up over 65 years.

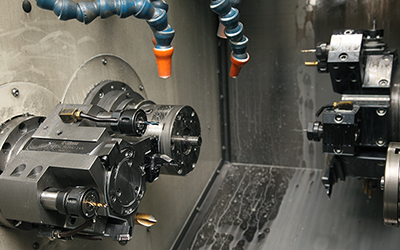

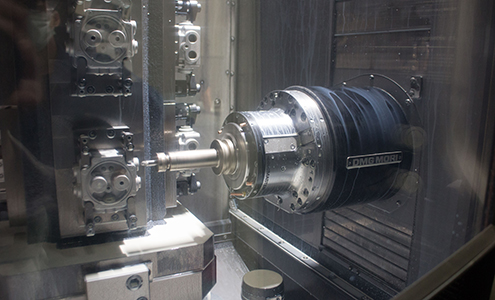

Turning

Depending on the shape, accuracy, material, size, quantity, etc. of the product From 60 NC lathes with various characteristics, we select the most suitable machine for the product and process it.

Example

A (1 to dozens)

Tsugami + Tsugami + Brother

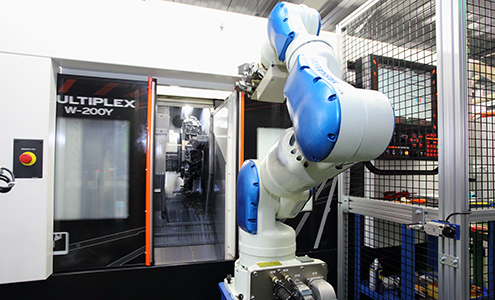

B (300 pieces)

Inte (robot)

C (5,000)

BNA (Bar Feeder)

| Work size | ・Cutting from bar Outer diameter φ0.5~φ65 Total length up to 200mm ・Cutting from cut piece Outer diameter φ4~φ250 Total length up to 300mm *Dependent on shape |

|---|---|

| Hole processing | ・Φ0.1 ~ It depends on the material hole depth. |

| Supported materials | ・ Various iron materials, SUS materials (However, surface grinding is limited to magnetic materials.) Aluminum materials, copper brass materials, resin materials (Example: SUM23L, SS, S45C, SCM435, SKD, SUH660, SUS316, SUS630, SUS303, SUS304, SUS430, A5052, A5056, A1052, C3604, C1100, phosphor bronze, POM, etc.) ・ Various difficult-to-cut materials and heat-resistant steel (Example: titanium, inconel, hardened steel, etc.) |

| Supported material shape | ・ Our standard handling materials: round materials, hexagonal materials, pipe materials ・ Materials supplied by customers: Various shapes (Example:forging, casting, die casting, drawing material) |

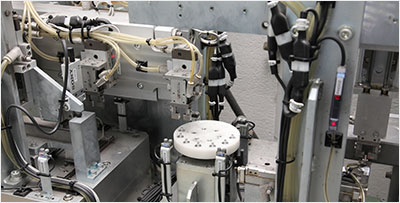

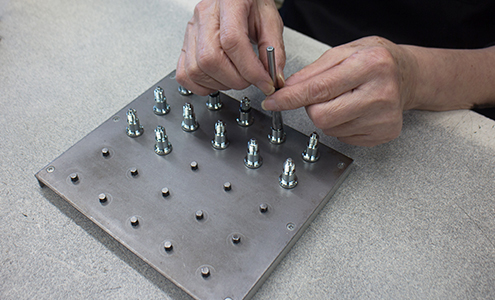

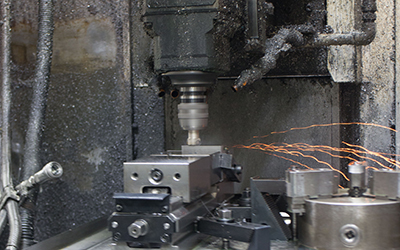

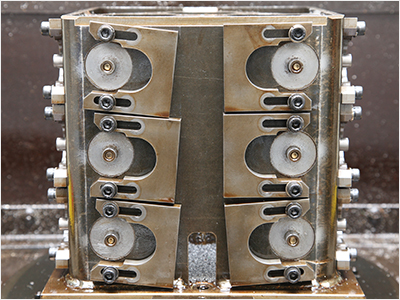

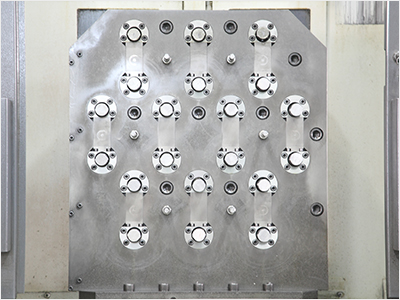

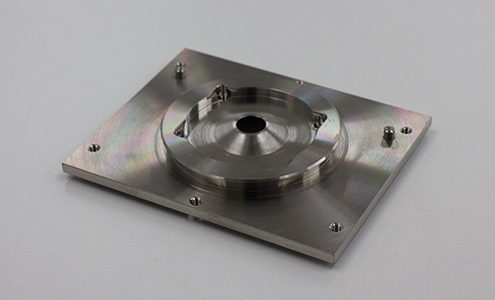

Machining

We manufacture jigs developed by our company according to the shape, accuracy, material, size, quantity, etc. of the product, and provide the product under the best conditions for the customer.

Example

A 1 piece

Precision vise

B 300 pieces

Hand tightening jig

C 5,000 pieces

Hydraulic automatic chucking jig

| Work size | ・3 axis Up to X:1000mm Y:600mm Z:650mm ・4 axis Up to X:720mm Y:700mm Z:650mm φ800mm 800kg 10 face palette, 12 face palette Palette size 500mm x 500mm ・5 axis (stroke) X:730mm Y:850mm Z:560mm C-120°~+30° φ730mm Maximum weight 500kg 2 palette Palette size 500mm x 500mm *Dependent on shape |

|---|---|

| Hole processing | ・ Φ0.1 ~ It depends on the material hole depth. |

| Supported materials | ・ Various iron materials, SUS materials (However, surface grinding is limited to magnetic materials.) Aluminum materials, copper brass materials, resin materials, CFRP (Example: SUM23L, SS, S45C, SCM435, SKD, SUH660, SUS316, SUS630, SUS303, SUS304, SUS430, A5052, A5056, A1052, C3604, C1100 , Phosphor bronze, POM, etc.) ・ Various difficult-to-cut materials and heat-resistant steel (Example:titanium, inconel, hardened steel, etc.) |

| Supported material shape | ・Materials handled by our company Block material (including plate), hexagonal, rounded and pipe ・Materials provided by the client Various shapes produced from forging, die casting, casting, etc. |

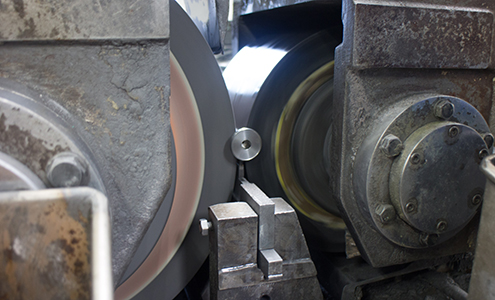

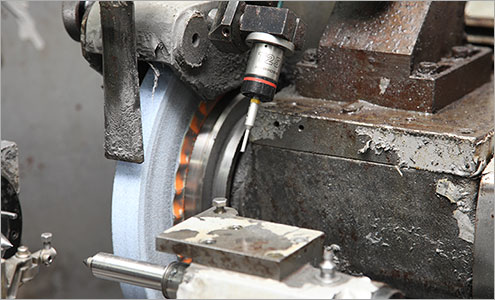

Grinding

We have surface grinders, cylindrical grinders, and centerless grinders, and can handle strict dimensional tolerances and surface roughness just by cutting. In addition, while many companies outsource grinding to specialists, Meiko Seiko Co., Ltd. can finish it in one stop, aiming to reduce costs and shorten delivery times.

| Work size | ・Cylindrical grinding (outer diameter only) φ6~φ80 Total length 250mm ・Centerless grinding (outer diameter only) φ3~φ100 Total length 100mm (Per stage) φ3~φ100 Total length 400mm (For grinding) ・Surface Grinding *Dependent on shape |

|---|---|

| Supported materials | ・ Various iron materials, SUS materials (However, surface grinding is limited to magnetic materials.) ・ Various difficult-to-cut materials and heat-resistant steel (Example: titanium, inconel, hardened steel, etc.) |

| Supported material shape | ・Materials handled by our company Block material (including plate), hexagonal, rounded and pipe ・Materials provided by the client Various shapes produced from forging, die casting, casting, etc. |

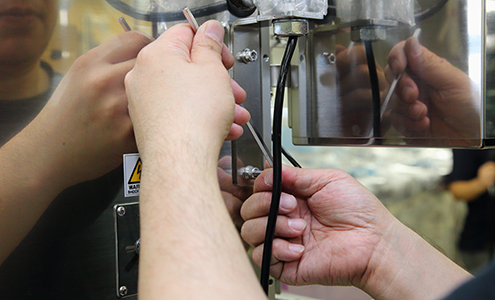

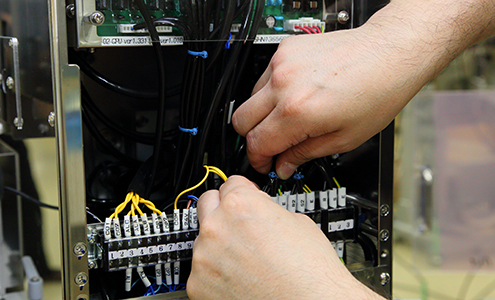

Assembly

Currently, we are assembling and sub-assembling aircraft, food, environmental equipment, and hydraulic equipment. Utilizing know-how familiar with various fields, we can handle any assembly. We also accept requests for individual assembly of supplied parts.