We so that our customers can place orders with confidence We propose the "best" with well-balanced technology, cost, and responsiveness.

Here at Nadaka Corporation, we don't claim to be the cheapest company in manufacturing. Rather, we pride ourselves in perfecting a manufacturing process which allows for immensely high quality, extensive support, flexibility throughout the manufacturing process, all while maintaining competitive cost performance. From initial prototype to mass production, we have the know-how and skill to make your product the best that it can possibly be.

-

One-stop support from initial prototype to mass production

We have a system that supports from one trial to mass production, and we propose prototype development in anticipation of mass production. You can rest assured that we can respond to the growth stage of the product.

-

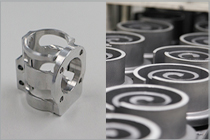

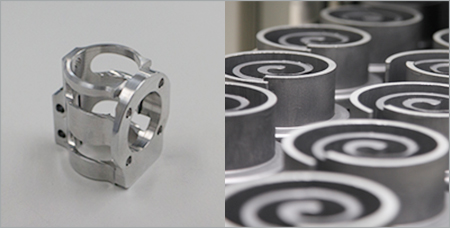

Technical expertise

Our expertise in turning and machining means we can offer support for even the most complex of projects.

-

Processing for difficult-to-cut metals

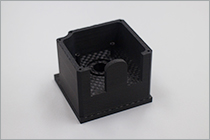

With the "Challenging Manufacturing DNA" that we have built up for over 65 years, we can process all kinds of difficult-to-cut materials such as Inconel, Titanium, and CFRP (Carbon Fiber Reinforced Plastic).

-

Wide variety Process the material of the material shape

Not only can it handle a wide variety of materials, but it can also process a wide variety of materials such as castings, die castings, lost waxes, forgings, bars, and cutting materials.

Proven results

We manufacture parts used in various industries by being evaluated for the know-how cultivated over many years, familiar with all kinds of metal processing, technology, cost, quality, proposal ability, and comprehensive balance that can be handled from trial production to mass production.

-

Automobiles

We are the one stop production center for turbo chargers and engine parts.

-

Aeronautics / Robotics

We have a proven track record in aircraft wings, doors, engine parts, etc. We support the development of precision parts that support the sky age.

-

Medical

As the need for precision medical devices grows alongside Japan's aging population, we take pride in developing parts for X-Ray machines, MRIs and more.

-

Hydraulic

We accept requests mainly for parts such as gear pumps and control valves. There are various materials such as casting, iron, and aluminum.

-

Robot

We will proactively propose the development of related parts for drones, smartphones, and industrial robots that are growing rapidly.

-

Railroad

We manufacture bolt embedding plugs for fastening devices that secure rails.

-

Measuring equipment

We manufacture aluminum parts including surface treatments in which lenses are incorporated, and interior-related parts.

-

Food

We process and assemble parts for labor-saving machines and automatic pouch loading machines in the industry.

Prototypes and mass production

It is possible to make a prototype from one piece even from a handwritten drawing. We have equipment that can handle everything from trial production to mass production, so we can meet the needs of our customers, such as quick delivery, small lots, and mass production. Nadaka Corporation will celebrate its 65th anniversary in 2019, and we will utilize the know-how we have cultivated since our founding to propose the best construction method assuming mass production from the prototype stage.

Prototypes

Our greatest strength is prototype development. Whether dealing with a hand-drawn design concept or a fully-fleshed out design, we offer the highest degree of support and technical expertise. Always considering cost performance alongside delivery deadlines while optimizing the product design for manufacturing flexibility. Further, we are partnered with Kyoto Shisaku Net, where we share ideas and maximize our technological capabilities through a network of likeminded companies in the region.

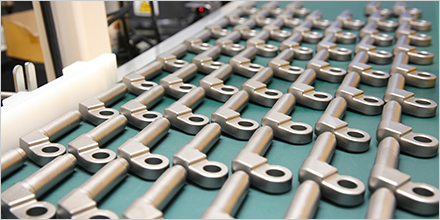

Mass production

Whether 100 parts or 1000 parts, from small and medium lot production to mass production (10,000 parts a month), we at Nadaka Corporation offer extensive support to meet your production needs. We operate an additional factory in Thailand in conjunction with our domestic factory in Japan, which provides the same degree of technical precision while drastically increasing the units of production.

Commitment to quality and the environment

We take our quality control and our responsibility to the environment seriously. We have acquired many certifications in both quality control and environmental responsibility. We strive to produce the highest quality parts while preserving resources for the future.

Comprehensive quality control system

By utilizing FMEA (Failure Mode and Effects Analysis), we eliminate potential risks of products and processes as much as possible. In addition, by paying attention to process capability (CP / CPK) and process performance index (PP / PPK), defects can be prevented.

Environmental Considerations

As a company based in Kyoto, the very city where the Kyoto Protocol was adopted, we at Nadaka Corporation take our responsibility to the environment seriously. We acquired the KES-STEP2 Environmental Management Certification in 2010 (KES-STEP2 is virtually identical to ISO 14001).

We established our Thailand factory in 2011 to further support our mass production abilities.

We established a Thai factory in 2011 and manufacture mass-produced parts centering on automobile-related parts. Japanese staff are stationed, and we utilize Japan's technical capabilities, quality control, and jig development capabilities as they are, and have a total of more than 100 local staff working 24 hours a day. In addition, the Thai factory has acquired ISO9001 : 2015 & IATF 16949:2016, and we have a more thorough quality control system in place.