Competitive and cost effective prototype development

Our greatest strength is prototype development. Whether dealing with a hand-drawn design concept or a fully-fleshed out design, we offer the highest degree of support and technical expertise. Always considering cost performance alongside delivery deadlines while optimizing the product design for manufacturing flexibility—these are the defining characteristics of Nadaka Corporation. Further, we are partnered with a larger manufacturing consortium, Kyoto Shisaku Net, where we share ideas and maximize our technological capabilities through a network of likeminded companies in the region. This allows for an additional degree of flexibility and optimization for your project.

Distinguishing factors

of the Nadaka factory

When it comes to prototypes, we are specialized for difficult-to-cut materials, complex and medium grade turning. Even with projects that may not be achievable from a technical perspective, we will work with the client to find the most competitive and technically feasible method to realize their goals. We process the highest quality parts for automobiles, aeronautics, hydraulics, construction equipment, measuring instruments, medical devices and more.

Some of the prototypes we develop:

Processing for difficult-to-cut materials and complex shapes

We are highly skilled in processing difficult-to-cut and complex materials. Whether stainless steel, titanium, inconel, heat resistant iron and other difficult-to-cut materials, we can cut within a precision of a few microns.

Medium grade turning

We are equipped to handle medium grade turning from 10mm to 200mm. We produce only the highest quality of parts for a wide variety of fields.

From medium lot production to mass production,

we support it all

With over one hundred pieces of various production equipment and measuring devices, over 50 years of experience, and an optimized manufacturing workflow, we are equipped to produce anywhere from 100-1000 parts at medium-lot production output, and can support production of up to 10000 parts per month at our mass production output. We are flexible to each clients' needs.

Distinguishing factors of Nadaka 's mass production system

At the Nadaka Corporation, we can handle mass production for even the most complex shapes and difficult-to-cut materials. Moreover, with both a Japan and Thai factory, we are able to simultaneously handle small lot, medium lot and mass production, all dependent on our clients' production needs.

Our factory floor and technical approach

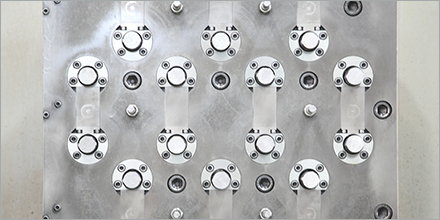

Excellent jig development

Our jigs can process highly specific and technically demanding parts that would simply be impossible for other companies to replicate.

Overseas Production Systems

Our factory in Thailand is capable of producing parts in the tens of thousands. We offer the high quality of our domestic Japanese factory while boasting a higher capability for mass production, and simultaneously reducing costs.